The Brushless 1000 N.m Electric Cordless Li-ion Battery Power Impact Wrench represents a leap forward in power tools, combining cutting-edge technology with immense torque capabilities to revolutionize the way heavy-duty tasks are undertaken.

Boasting a staggering 1000 N.m of torque, this electric impact wrench can effortlessly tackle demanding tasks, from loosening stubborn bolts on heavy machinery to fastening large nuts in construction projects. This torque level places it in a league of its own, making it an invaluable asset for professionals in fields such as automotive repair, construction, and industrial maintenance.

Li-ion battery technology ensures a longer runtime and shorter charging cycles, enhancing the efficiency of the tool. This means less downtime waiting for the battery to recharge and more time spent on productive work. Additionally, modern battery management systems contribute to the overall safety of the tool, preventing overcharging and over-discharging, thus extending the battery's life.

The cordless design of the impact wrench offers the convenience of unrestricted movement without the hassle of cords and power outlets. This portability allows users to work in tight spaces or remote locations with ease.

Brushless 1000 N.m electric cordless li-ion battery power impact wrench

-

Specifications

Battery Voltage: 21V Battery Capacity: 4.0Ah/10C No-load Speed: 0-2000r/min Max Torque: 1000N.m Max.Impact: 0-2200ipm Output Shaft: 1/2" Square head -

Feedback

PRODUCT ADVANTAGES

-

High energy density: Lithium batteries have a high storage energy density.

High energy density: Lithium batteries have a high storage energy density. -

Long service life; More than 90% of the tools use brushless motors.

Long service life; More than 90% of the tools use brushless motors. -

Light weight, small size, more easier to carry.

Light weight, small size, more easier to carry. -

High efficiency, small vibration, easy to operate.

High efficiency, small vibration, easy to operate.

4.0AH 21V

LI-ION2. A variety of battery capacities are available, compatible with all models, one battery can be used for multiple purposes, saving you money.

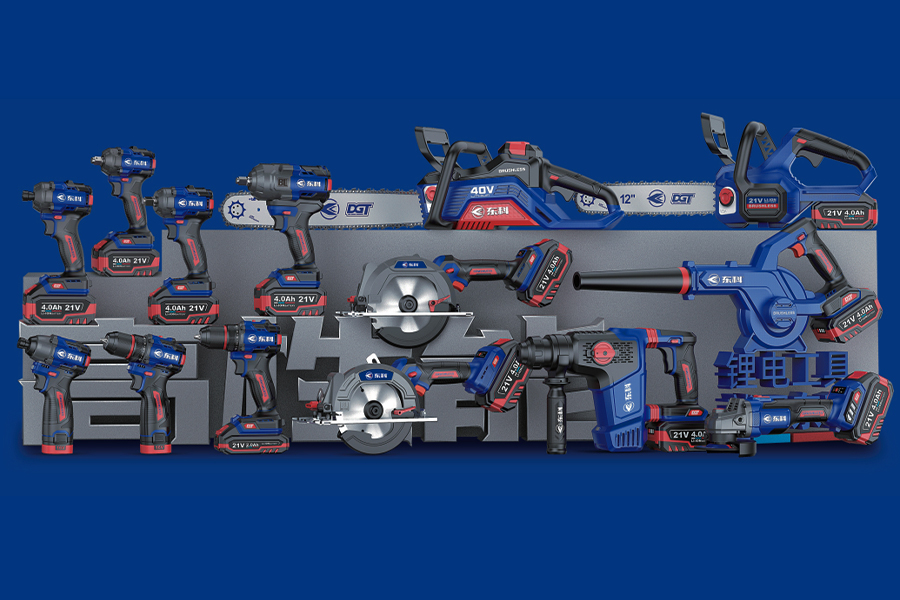

PRODUCT

Since its establishment, the company has continuously introduced advanced technology and equipment domestically and abroad and accumulated a lot of technical talents engaged in the research and development, design, and production of charging tools. The company integrates product research and development, design, production, and sales, providing a full range of nickel-cadmium charging drills, lithium charging drills, batteries, chargers, and other high-quality and reliable products. Strive to provide customers with quality products and services, the company's production of lithium batteries domestic and international customers unanimous recognition and praise!

-

1. Environmental performance: zero emissions and low noiseZero exhaust emissionsThe lithium battery pruning shears are powered by lithium batteries and do not produce harmful gases such as CO ₂ and NOx during o...

READ MORE -

1. Maintenance points Cleaning and rust preventionAfter using the lithium reciprocating saw, the dust and moisture around the blade should be cleaned in time to prevent rust and malfunction. Pay special attenti...

READ MORE -

1. Impact energy and drilling diameterThe impact energy (in joules/J) determines the penetration force.The upper limit of drilling diameter needs to match the actual requirements. 2. Motor and battery performan...

READ MORE -

What are the significant advantages of Lithium Electric Angle Grinder compared to traditional tools?

1. Portability and flexibilityThe Lithium electric angle grinder is powered by lithium-ion batteries, which are lightweight and efficient, making the tool more portable. 2. SafetyThe Lithium electric angle grin...

READ MORE -

1. High portability and flexibility:The cordless lithium polishing angle grinder is powered by a rechargeable lithium-ion battery and does not rely on a power socket. Therefore, it can be freely moved anywhere ...

READ MORE

A brushless 1000 N.m electric cordless Li-ion battery power impact wrench is a powerful and versatile tool designed for various automotive and construction applications. Let's break down the key components and features of this tool:

1.Brushless Motor: The "brushless" designation indicates that the wrench uses a brushless electric motor. Brushless motors are more efficient, durable, and require less maintenance compared to traditional brushed motors. They also provide better control over the power delivery.

2.1000 N.m of Torque: This impact wrench is capable of delivering a maximum torque of 1000 Newton-meters (N.m), which is a measure of rotational force. This level of torque makes it suitable for tasks that require a high amount of force, such as removing stubborn bolts and nuts.

3.Cordless Design: Being cordless means it is powered by a rechargeable lithium-ion (Li-ion) battery. This design offers greater mobility and convenience compared to corded impact wrenches, as you can use it in various locations without the need for a power outlet.

4.Li-ion Battery: Lithium-ion batteries are known for their high energy density, which provides longer runtimes and quicker charging compared to other battery types. They also have a low self-discharge rate, meaning the battery will hold its charge when not in use for an extended period.

5.Variable Speed and Torque Settings: Many cordless impact wrenches come with adjustable speed and torque settings, allowing you to tailor the tool's performance to different tasks. This feature is particularly useful for avoiding over-tightening or damaging delicate components.

6.Impact Mechanism: Impact wrenches use a specialized mechanism that delivers rotational impacts to loosen or tighten fasteners quickly. This mechanism makes them highly effective for tasks like changing tires, assembling structures, or working on heavy machinery.

7.LED Lighting: Some models feature built-in LED lights to illuminate the work area, making it easier to work in dimly lit or confined spaces.

8.Ergonomic Design: A comfortable and ergonomic grip is essential for reducing user fatigue during extended use. Look for features like rubberized handles and well-balanced weight distribution.

9.Battery Indicator: It's helpful to have a battery status indicator so you can monitor the remaining charge and plan recharging accordingly.

10.Accessories: Impact wrenches often come with a variety of sockets and adapters to fit different fastener sizes and types.When using a high-torque impact wrench, it's crucial to follow safety precautions, such as wearing appropriate protective gear and ensuring the tool is correctly calibrated for the task at hand. Additionally, be aware of the potential for over-tightening or damaging fasteners, particularly on delicate components, and use the appropriate torque settings or attachments when necessary.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体