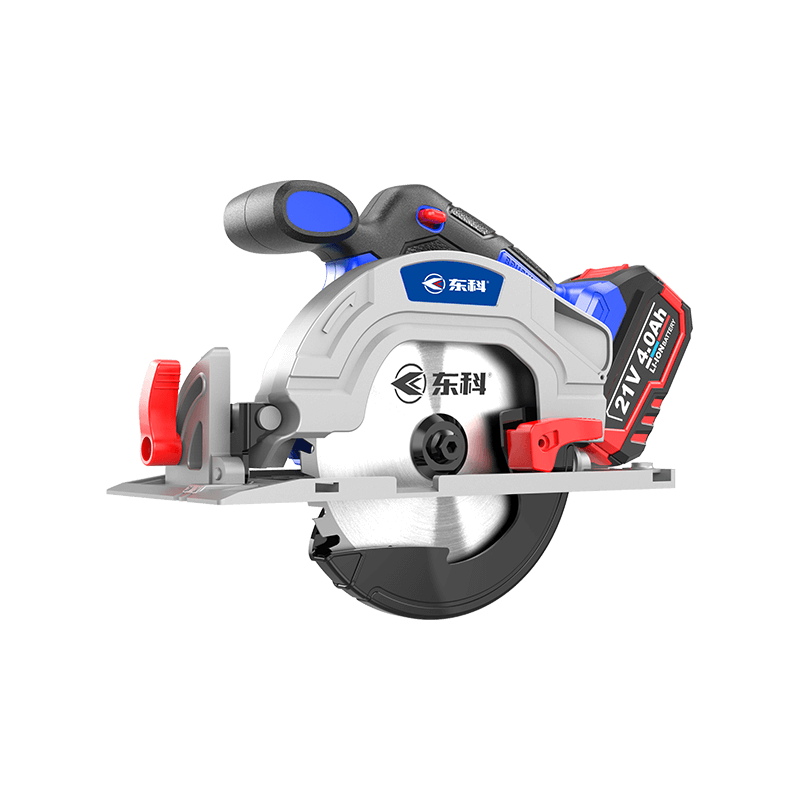

Why does this lithium cordless drill use brushless motor technology?

The reason why this lithium-ion cordless drill chooses to use brushless motor technology is that brushless motors have significant advantages over traditional brushed motors. Here are the specific reasons:

High efficiency: Traditional brushed motors rely on direct contact between carbon brushes and rotating parts to transmit electrical energy. This contact method not only generates friction, but also easily causes energy loss and a decrease in motor efficiency due to wear and tear of the carbon brushes. The brushless motor completely abandons this contact method. It uses an electronic control system to precisely control the current, causing the magnetic field to interact and drive the motor to rotate. This method greatly reduces energy loss, because the energy is almost completely converted into the mechanical energy of the motor, rather than heat energy or other forms of energy loss. Therefore, the brushless motor is more efficient in the energy conversion process, allowing this lithium-electric cordless drill to provide longer running time and stronger power output with the same battery capacity.

Long life: In traditional brushed motors, the carbon brush is a wearing part. As time goes by and the frequency of use increases, the carbon brush will gradually wear out, eventually leading to reduced motor performance or even failure. Brushless motors, on the other hand, have no carbon brushes and are completely free from the adverse effects of friction and wear. Brushless motors have a longer service life and users can use them for a long time without worrying about motor performance degradation or damage. This not only saves users the cost of replacing the motor, but also improves the overall use value and cost-effectiveness of the tool.

Low noise: Brushless motors also operate with relatively low noise. Since brushless motors do not have the friction of carbon brushes, the noise generated when the motor is running will be greatly reduced. This is an important advantage for users, because a low-noise environment is not only more comfortable, but also avoids noise interference that affects other work or activities. Especially in situations where a quiet environment is required, the low noise characteristics of brushless motors are particularly important.

High Reliability: The design of the brushless motor makes it more reliable. Since there are no wearing parts such as carbon brushes, the internal components of the motor are less susceptible to wear and damage. At the same time, the electronic control system of the brushless motor can monitor the operating status of the motor in real time. Once an abnormality is discovered, measures can be taken immediately to protect it, thereby avoiding damage to the motor due to overload, overheating, etc. This high-reliability design ensures the stability and durability of the motor, allowing this lithium-electric cordless drill to operate stably in various complex working environments and provide users with reliable power support.

To sum up, this lithium cordless drill chooses to use brushless motor technology because brushless motors have the advantages of high efficiency, long life, low noise and high reliability. These advantages make brushless motors the preferred technology in the field of modern power tools, providing users with a better and longer-lasting experience.

-

Feedback

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体