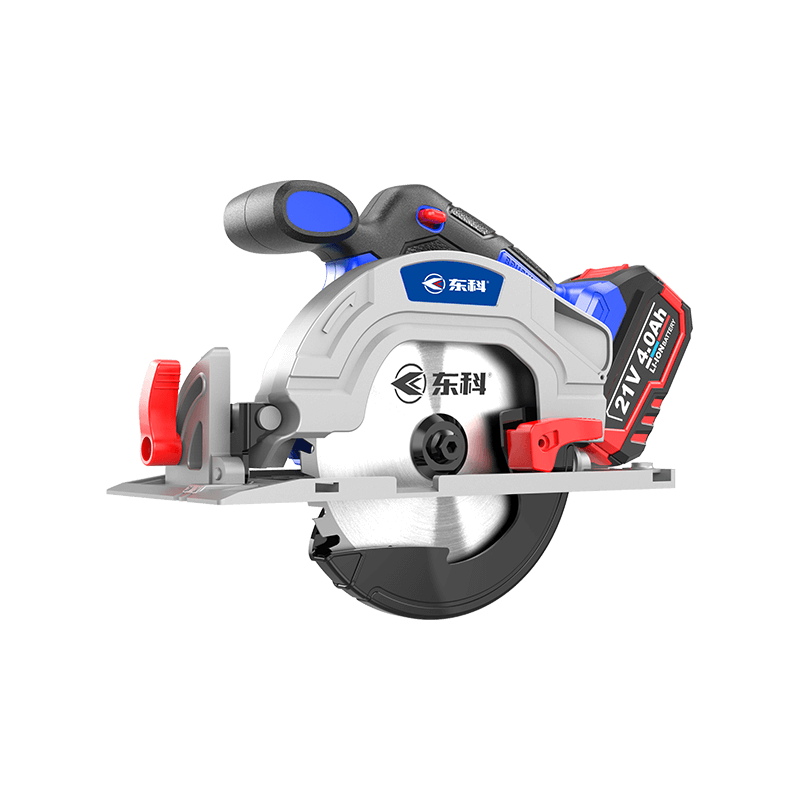

What are the specific advantages of Brushless 1000 N.m electric cordless li-ion battery power impact wrench over traditional brushed motors?

High efficiency and low energy consumption

Brushless 1000 N.m electric cordless li-ion battery power impact wrench replaces traditional carbon brushes and commutators with electronic commutators, reducing energy loss during the conversion process, thereby improving the working efficiency of the motor. This means that under the same torque output, the brushless motor can consume less power, which means longer single-charge working time and lower energy consumption costs for the 1000 Nm electric cordless lithium-ion battery power impact wrench produced by Nantong Dongke Tools Co., Ltd.

Long life and low maintenance

When the traditional brushed motor is running, the carbon brush will rub against the commutator, which will not only cause wear, but also generate sparks and carbon powder, affecting the performance and life of the motor. The brushless motor avoids this problem because the electronic commutator does not require physical contact, which greatly reduces wear and failure rate. Nantong Dongke Tools Co., Ltd. relies on its professional R&D and manufacturing capabilities to ensure that the life of brushless motors far exceeds that of traditional brushed motors, while reducing users' maintenance costs.

Low Noise and Low Vibration

Brushless motors run more smoothly because the electronic commutator can more accurately control the direction and timing of the current, thereby reducing the vibration and noise of the motor. This means a more comfortable and focused working environment for users who need to use impact wrenches for a long time. Nantong Dongke Tools Co., Ltd. pays special attention to reducing noise and vibration during the design and manufacturing process to provide a better user experience.

High Precision and Programmability

The control of brushless motors is more flexible and precise because the electronic commutator can adjust the size and direction of the current in real time for more refined control. This makes brushless motors perform better in applications that require high-precision control. In addition, the programmability of brushless motors also provides companies with more room for innovation, and can customize the performance and functions of the motor according to the specific needs of users.

-

Feedback

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体