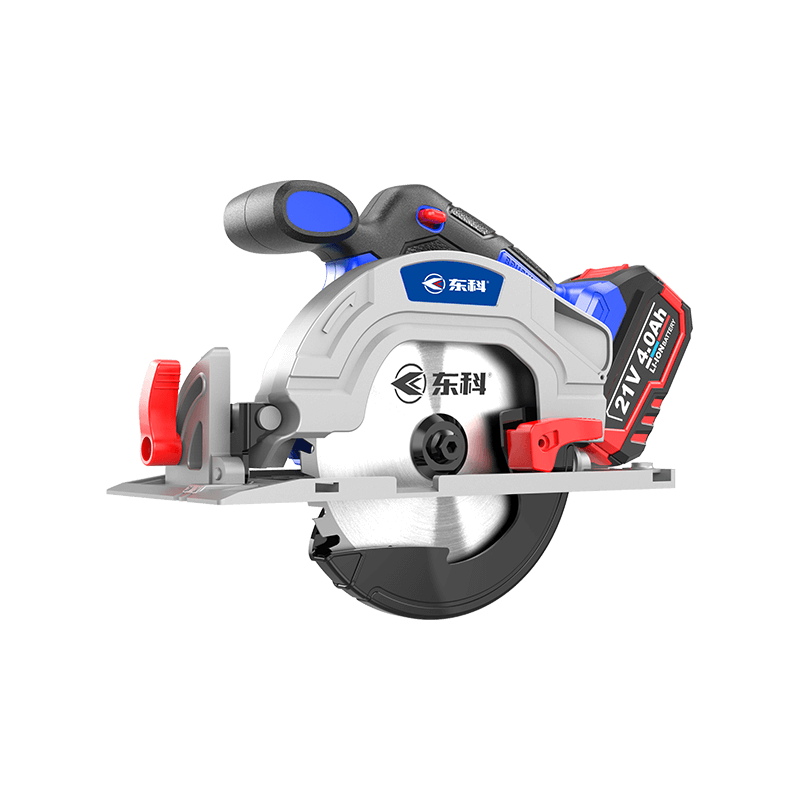

What type of motor does the 21V Cordless lithium polishing angle grinder use?

1. Brushless motor type

The 21V Cordless lithium polishing angle grinder uses a brushless motor, also known as a brushless DC motor (BLDC), which is a type of motor that uses an electronic commutator (rather than a traditional mechanical commutator) to drive the motor rotor. This type of motor usually consists of a stator, a rotor, an electronic commutator, and a controller.

2. Advantages of brushless motors

High efficiency and energy saving:

Brushless motors use electronic commutators to accurately control the direction and size of the current, so that the motor loses less energy during operation and is more efficient.

Compared with brushed motors, brushless motors can provide higher speeds and torques at the same power while reducing power consumption.

Long life:

Brushless motors do not have wearing parts such as carbon brushes and commutators, so the possibility of mechanical wear and failure is reduced.

Under normal circumstances, the service life of brushless motors is much longer than that of brushed motors, reducing the cost of replacing motors and repairs.

Low noise:

The running noise of brushless motor is relatively small because the electronic commutator reduces mechanical friction and vibration.

This makes the polishing angle grinder quieter during use and improves the user experience.

Good speed regulation performance:

The brushless motor can achieve precise speed regulation function through the electronic controller, and the user can adjust the motor speed and torque as needed.

This speed regulation performance makes the polishing angle grinder more suitable for polishing tasks that require precise speed control, improving the polishing effect and efficiency.

Higher safety:

The brushless motor does not use carbon brushes, so it does not generate sparks and arcs, reducing the risk of fire and electric shock accidents.

This makes the polishing angle grinder safer and more reliable during use, especially when used in flammable and explosive environments.

Low maintenance cost:

Since the brushless motor has no wearing parts such as carbon brushes, the maintenance cost is relatively low.

Users only need to clean the motor and check the working status of components such as the controller regularly, without frequently replacing wearing parts such as carbon brushes.

Environmental protection:

The brushless motor reduces mechanical friction and vibration, reduces noise pollution and energy consumption.

At the same time, due to the long service life of brushless motors, the disposal and recycling costs of waste motors are reduced, which has positive significance for environmental protection.

-

Feedback

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体