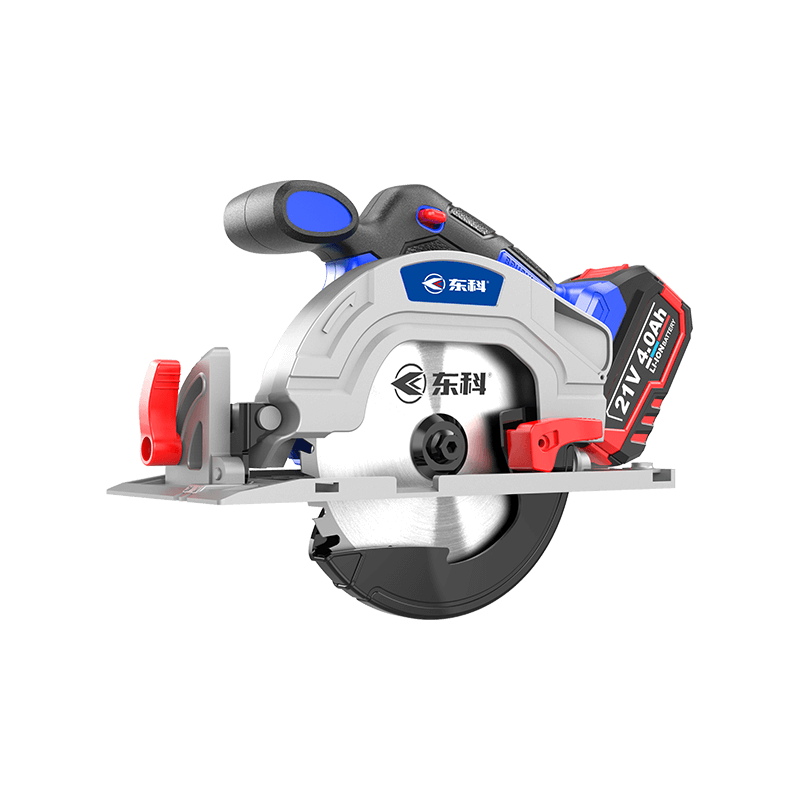

What effect does a higher no-load speed have on cutting?

1. Improved cutting efficiency

A higher no-load speed means that the saw blade rotates more times per unit time, which allows it to cut materials faster. This can significantly shorten the time required for cutting and improve production efficiency. Especially when dealing with large amounts of material or when cutting tasks need to be completed quickly, high-speed circular saws can play a greater advantage.

2. Improved cutting quality

Smoother cutting surface:

A high-speed saw blade can remove material more quickly when cutting, reducing friction and heat accumulation, thereby reducing the heat-affected zone and maintaining the original properties of the material. This helps to obtain smoother and more precise cutting edges.

Reduce burrs and saw marks:

When the saw blade rotates at a higher speed, it can cut into the material more quickly and move along the predetermined path, reducing burrs and saw marks caused by vibration or instability of the saw blade.

3. Impact on materials and saw blades

Impact on materials:

When dealing with softer or deformable materials, high-speed cutting can reduce thermal deformation and hardening of the material. However, when dealing with hard materials, too high a speed may cause increased wear of the saw blade or generate excessive heat, thus affecting the cutting quality and blade life.

Impact on saw blades:

Although high speed can improve cutting efficiency and quality, it will also increase the wear rate of the saw blade. Therefore, when choosing high speed cutting, it is necessary to comprehensively consider the material, durability and characteristics of the saw blade for cutting.

4. Safety and noise considerations

Safety:

Although high speed can improve cutting efficiency and quality, it may also increase operating risks. Therefore, when using high speed circular saws, it is necessary to strictly follow the safety operating procedures, wear appropriate protective equipment, and ensure the safety of the working area.

Noise:

Saw blades with high speeds will produce more noise when cutting. This may have an adverse effect on the operator's hearing and the working environment. Therefore, when using woodworking electric circular saws, appropriate noise control measures need to be taken, such as wearing earplugs or setting up sound barriers in the working area.

-

Feedback

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体