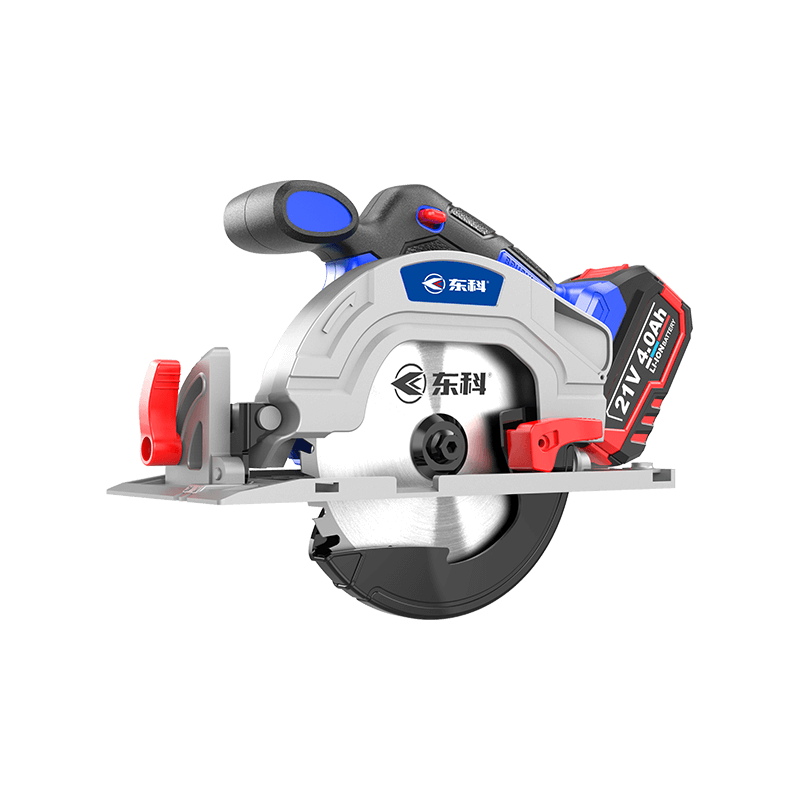

How does the brushless motor used in the 21V Cordless lithium polishing angle grinder improve durability and reduce maintenance requirements?

The brushless motor used in the 21V cordless lithium electropolishing angle grinder significantly improves durability and reduces maintenance requirements in many aspects. The brushless motor replaces the traditional mechanical commutator and brushes with an electronic commutator, which fundamentally Friction and wear between brushes and commutator are eliminated. This design not only reduces performance degradation caused by brush wear, but also significantly extends the service life of the motor. Since the brushless motor has a more compact structure and reduces friction parts in traditional motors, mechanical losses are also reduced accordingly, further improving the durability of the motor.

Brushless motors are precisely controlled through an advanced electronic control system and can respond to changes in load almost instantaneously. This immediacy not only ensures the continuity of the work process, but also allows the tool to quickly reach and maintain the required speed and power when needed, thus significantly improving work efficiency. At the same time, the design of the brushless motor reduces reactive power losses, that is, electrical energy consumption that is not directly converted into useful work, such as resistor heating, electromagnetic radiation, etc. This efficient energy conversion allows the battery's energy to be more fully utilized, extending the working time after a single charge and reducing the need for frequent charging.

Because brushless motors reduce mechanical friction and vibration, their operating noise levels are significantly reduced compared to traditional brushed motors. This not only provides operators with a quieter, more comfortable working environment, but also helps reduce the risk of hearing damage that may result from prolonged exposure to high-noise environments. In addition, the low-noise design also improves the overall working experience, allowing operators to focus more on the task itself, improving work efficiency and accuracy.

Since there are no wearing parts such as brushes and commutators, users do not need to worry about the wear and replacement of these parts, thus greatly reducing the cost of regular maintenance and upkeep. In addition, when a brushless motor occasionally fails, its simple structure and fewer parts make troubleshooting and repair relatively easy. This not only shortens maintenance time and reduces production losses due to downtime, but also reduces the professional skills and tool requirements required for maintenance, allowing users to perform maintenance and upkeep more autonomously.

With the advancement of technology, brushless motors are gradually incorporating more intelligent elements. By integrating advanced sensors, control algorithms and communication interfaces, brushless motors can automatically adjust and optimize according to the actual needs of the application scenario. For example, in a polishing angle grinder, the brushless motor can automatically adjust the speed and torque according to the hardness and surface roughness of the material to achieve the best polishing effect. This intelligent design not only improves the performance of the equipment, but also makes the equipment easier to control and use, reducing the requirements for operator skills.

The brushless motor used in the 21V Cordless lithium polishing angle grinder has excellent performance in reducing wear, improving efficiency, reducing energy consumption, reducing maintenance requirements, and being intelligent and adaptable. These advantages make brushless motors one of the important development directions in the field of modern power tools.

-

Feedback

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体